Disc Type Automatic Bedding Material Packaging Line

I. Function:

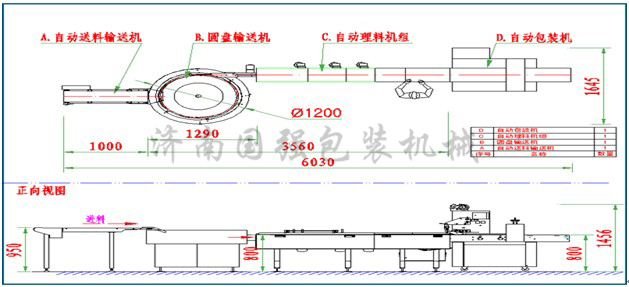

Quantity: design 1 set of the automatic loading packaging line, packaging speed 270 bags/min

II. Drawing:

III. Description:

The diagram shows that the automatic feeding and packing line is combined into 4 parts.

A. Automatic feeding part.

Workers only need to put the bread into the automatic feeding machine, while according to the material situation reasonable to the disc conveyor

This part and precision, to ensure smooth feeding without blocking, without manual intervention, continuous operation.

B. Turntable array unit (1 set) part.

Automatic production line equipment also has a turntable display conveyor, rotating with different internal and external disk speeds, centrifugal force will order the products one by one to be transported out.

C. Automatic sorting device (1 set) part.

Automatic feeding part with buffer storage function to avoid stopping the number of the packaging machines. Realize the speed and position of the automatic packaging machine matching, to ensure that the products entering the packaging machine are packed in an accurate position and at a comparable speed. Automatic packaging machine when the number of products is not enough, automatically start packaging machine materials, rather than manual operation.

Automatic filling part of the structure of the performance advantages: humanized design, simple structure, easy operation, easy cleaning and disinfection of sanitary equipment; conveyor belt with automatic function (free adjustment), free tools for quick disassembly.

D. Pillow packaging machine (1 set) part.

High-speed pillow packaging machine installed with date printer. Simple and convenient operation, each machine is equipped with double paper support rollers.

IV. Conveying and packaging system materials:

A. Feeding and packaging system transport equipment, pushing the block, or part of direct contact with the material, all using SUS304 standard specifications.

B. Feeding and packaging system frame surface and drive parts, the material is carbon steel, nickel, aluminum

C. The conveyor belt is PU food grade.

D. Feeding system photoelectric eye is Germany Schick brand

E. Sensor: Taiwan Delta brand.

F. Encoder: Japan Omron brand.

V. Brands of components of the feeding line

| ITEM | NAME | BRAND | MODEL | ORIGIN |

Main | PLC | DELTA | DVP28SV11R | TAIWAN |

Transducer | DELTA | VFD-EL040 | TAIWAN | |

Touch screen | WE INVITE | TK6070IK | TAIWAN | |

Temperature meter | OMRON | E5EZ-Q3T | JAPAN | |

executive component | Date printer | DIKAI | DK-1000A(600MM) | SHANGHAI |

Motor | TIANYANG | 180W | CHINA | |

Planet-gear box | EDELI | 370W | TAIWAN | |

Turbo-gear box

| XINGGUANG | 30MODEL, 1:10 | CHINA | |

Pneumatic parts | SMC | |||

Convey belt | HABAS | |||

Electrical sensing element | Encoder | OMRON | JAPAN | |

Photocell eye | SICK | WT9-21V130 | GERMANY | |

Approach switch | OMRON | 12-04NK-M | JAPAN | |

Groove switch | SUNX | PM-K44 | JAPAN | |

| Electrical auxiliary components | Solid realay | FRANk | GERMANY | |

Buttons | SCHNEIDER | XB7EA31L, XB7-EA2K | FRANCE | |

Air switch | MINGYI | C45N6A | TAIWAN | |

Relay | OMRON | JAPAN | ||

Switch | MINGYI | Output 24V, 2.1A | TAIWAN | |

material | Frame surface | CARBON STEEL | ||

Driving parts | SS, NICKEL, AL | |||

Parts touch with food | STAINLESS STEEL SUS304 |

Add:Jinan City, Shandong Province, Huashan Industrial Park

Tel:0531-88772199

Mobile:18660150289

Friend Links: Packer Food packaging machine Granule packing machine Packaging machinery Powder packaging machine Ji'nan Guoqiang Morning sun Technology Liangshan used car Packaging Machine/Packaging Machinery/Packing Machine

Wechat Code

Jinan Guoqiang Machinery Equipment Co., Ltd

鲁ICP备18053375号-1

Unified service hotline 0531-88772199